Optical surface desing and characterization

- Aki Matilainen

- Jan 2

- 3 min read

Updated: Jan 5

Optical surfaces play a crucial role in many technologies. Understanding how surfaces are designed and characterized helps engineers and scientists to understand the overall process of utilizing surfaces in optics. This post explores some of the key methods and aspects of optical surface characterization.

What is optical surface characterization?

Optical surface characterization involves design, measuring and analyzing the surfaces used in optical components. The goal is to assess how well the surface meets it's design specifications. Optical surfaces are designed by using theoretical materials. Theoretical materials are obtained by measuring the light matter interaction and modelling the involved physical interactions. The accuracy of modelling and measurement uncertainty defines how well the final design and measured optical response fits to each others.

Key parameters assessed in optical surface design and characterization

Reflectivity and transmission

Measuring how much light is reflected or transmitted defines optical performance. Absorbance and emittance can be determined as well.

Surface topography, roughness, flatness and waviness

Physical textures itself can interact with light in many ways from nanophotonics to geometrical ray-optics.

Surface durability

Substrate and applied coatings must be physically and chemically compatible to meet requirements such as adhesion and wear resistance that the final product will experience in it's lifetime.

Common techniques for optical surface characterization

Several methods are used to characterize optical surfaces, each with strengths and limitations depending on the application.

Interferometry

Interferometry uses the interference of coherent light waves to make extremely precise measurements of distance, displacement and vibration by splitting a light beam, sending the beams along different paths, and then recombining them to analyze the resulting interference pattern.

Optical spectrosopy

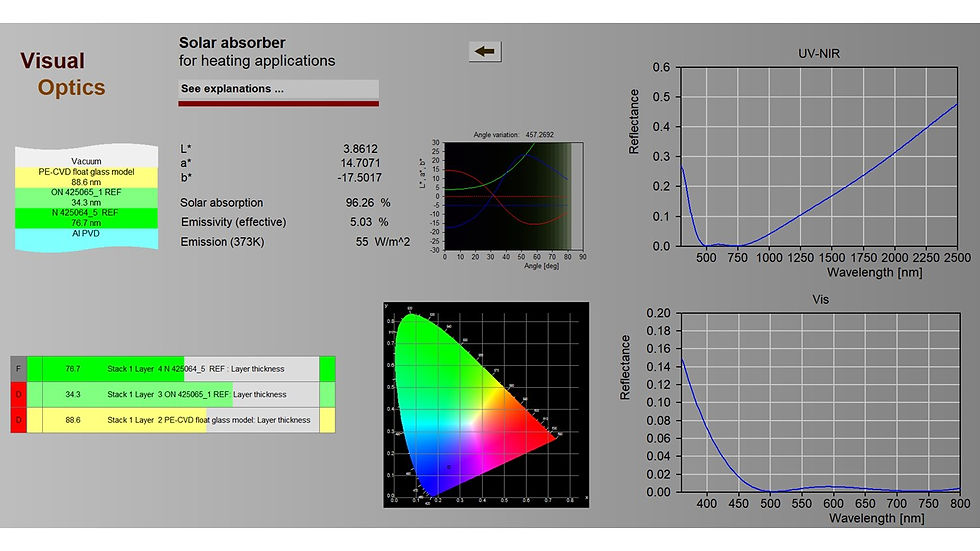

NextGenSurfaces Finland Oy utilizes a wavelength resolved UV/VIS/NIR and FTIR spectroscopy to analyse optical properties of surfaces. Spectrometers are equipped with varying optical accessories such as integrating spheres to handle varying geometrical aspects.

Design and simulation

Optical design software offers a powerful tool to analyse different optical systems, including features such as surface roughness, composition gradient and density variations.

The goodness of simulated reality depends on on the accuracy of simulation model. For very thin, <10 nm films a rather complicated simulation model may be required for accurate modelling as film growth under typical conditions takes place as a formation of small island of materials and resulting grain boundaries which density gets smaller towards the top of layer. In such cases some basic understanding on light-matter interactions is required after which design software can be conveniently applied. After certain thickness the layer can be treated as a homogeneous layer, if that is the intention, and the refractive index and absorption coefficient of material are sufficient to predict optical response.

Refractive index

Describes the wavelength and speed of light in material, compared to that one in a vacuum. It would also tell the amount of reflection and refraction at the interface for given incident angle.

Absorption coefficient

Describes how the amplitude of wave, it's electric field, corresponding to number of photons, is attenuated as the light travels in material.

Basic light-matter interactions

For building a simulation model for obtaining refractive index and absorption coefficient for a given wavelength, a set of interactions and related parameters would need to be applied.

Interband transitions

Light can raise electrons from a valence to a conduction band in almost any kind of material if the energy of photon is high enough. This causes high absorption in some energies, typically in ultraviolet (UV).

Vibrational modes

Refers into acceleration of charged atoms in material. Because atoms are heavier than electrons, vibrational modes typically take place in infrared (IR).

Acceleration of free charge carriers

Takes place in negatively charged electrons or positively charged carriers that can move in material.

Wave interference

When propagating medium thickness is much larger than the wavelength, so called ray-optics and laws of reflection and refraction can be used to analyze optical system. In thin film optics the wave interference is equally important concept to be utilized.

Concluding worlds

As in anywhere, energy is conserved in optical surface as well. It's either reflected, absorbed or transmitted. The optical design define at what ratios, in which directions and on what wavelengths it takes place. Optical characterization verifies the design.

After design and prototype manufacturing, the lifetime of surfaces at given application is assessed eg. by accelerated environmental testing.

If you need to manipulate light within a surface, NextGen Surfaces Finland can help you to design, produce and characterize such surfaces.